Edible Oil Refining Production Line

Edible oil refining machine is used for processing various crude vegetable oil, such as crude sunflower seed oil, soybean oil, peanut oil, palm oil, palm kernel oil, canola oil, coconut oil, cotton seed oil, flaxseed oil, etc.to remove gum and impurities in oil, and improve oil quality by adjusting its color , taste, and storage time. The main process of cooking oil refining are degumming, deacidification, bleaching, and deodorization.

Edible oil refining machine is used for processing various crude vegetable oil, such as crude sunflower seed oil, soybean oil, peanut oil, palm oil, palm kernel oil, canola oil, coconut oil, cotton seed oil, flaxseed oil, etc.to remove gum and impurities in oil, and improve oil quality by adjusting its color , taste, and storage time. The main process of cooking oil refining are degumming, deacidification, bleaching, and deodorization.

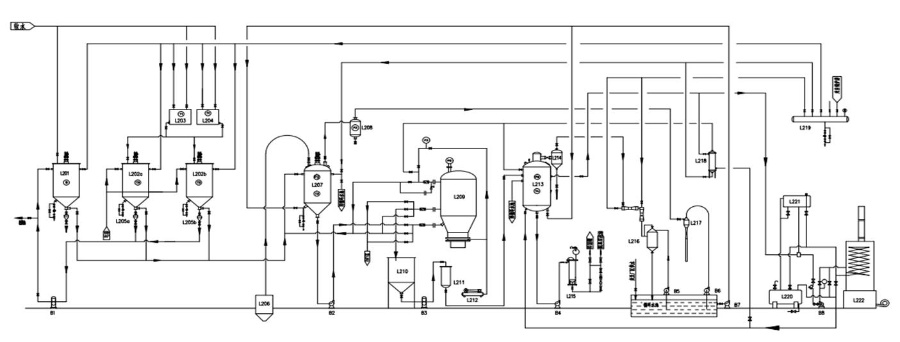

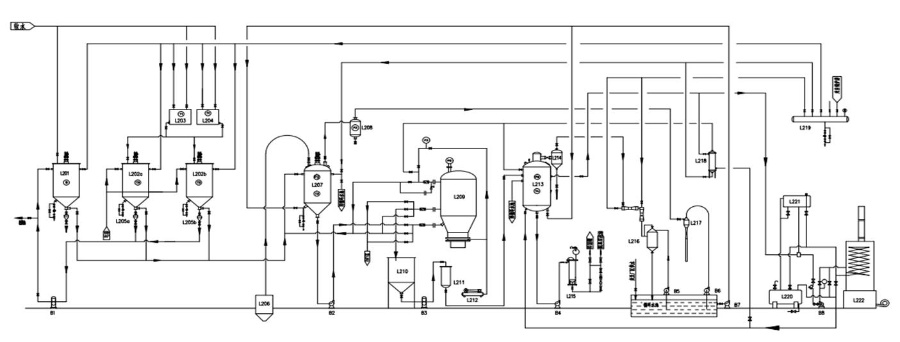

Flowchart of Crude Edible Oil Refining Production Line

Main Process of Crude Cooking Oil Refining Production Line

Degumming process: There is phospholipid in crude oil, it has an strong ability to absorb water, when phospholipid absorb water, it is easy to cause oil rancidity, it is not good for oil storage and usage. Hydration degumming is to use the hydrophilicity of phospholipids and other soluble impurities to add a certain amount of hot water or diluted alkali, salt, phosphoric acid and other electrolyte aqueous solutions to hot crude oil under stirring, so that the soluble impurities in it absorb water and condense, and then settle to separate the oil residue and degummed oil, and the degummed oil enters the alkali refining process.

Deacidification process :This process is to use alkali refining method to remove fatty acid in crude oil, free fatty acid influence oil smell, and it is easy to cause oil oxidation when heating. Alkali refining of oils and fats is to add a certain amount of alkali solution to the degummed oil, so that the free fatty acids in the degummed oil react with the alkali solution to remove the free fatty acids in the degummed oil. After the degummed oil is heated to a suitable temperature, an appropriate amount of alkali solution is added and it is put into the dephosphorization and deacidification pot for reaction. After a certain reaction time, it is settled to separate the soapstock and alkali refined oil, and the alkali refined oil enters the water washing process.

Washing process: Before alkali refined oil goes to decolorization process, the wash need to be washed in order to completely separate soapstock with oil. Alkali refined oil is washed with hot water, and the water washing temperature is 10-15° higher than the oil temperature. It is washed 2-3 times until the residual soap content in the oil meets the process indicators.The washed oil enters the next decolorization process.

Decolorization process: The alkali refined oil goes to decolorization process, there are pigments in oil, such as chlorophyll, carotenoid, etc. They influence oil color, cause oil color deep, so we will add bleaching earth into oil in order to remove pigment. Turn on the vacuum pump, wait for the decolorization pot to be vacuumed for about 5 minutes, open the valve of the oil refining pot, and suck the oil into the decolorization pot. First, dry the alkali refined oil, then add white clay and stir and mix to decolorize. The mixture of oil and white clay from the decolorization pot passes through the blade filter to obtain decolorized oil.

Deodorization process: The decolorized oil goes to deodorization process, the purpose is to remove bad smell of oil, after this process. The decolorized oil from the decolorization section will enter the deodorization section to remove free fatty acids and some small molecular substances that cause odor, such as aldehydes, ketones, and hydrocarbons. The deodorization pot is used to remove these substances with steam under high vacuum conditions. The removed fatty acids are collected in the fatty acid collector and pumped into the receiving tank as a by-product.

A water ring vacuum pump is designed in the vacuum system of the deodorization section to capture the odor extracted by the deodorization vacuum with circulating water, eliminating the odor pollution during the deodorization process.

Filtration process: the deodorized oil will be purified again by filter, then you can get finish oil, and store the oil into oil tanks, or fill oil into bottles through oil filling production line.

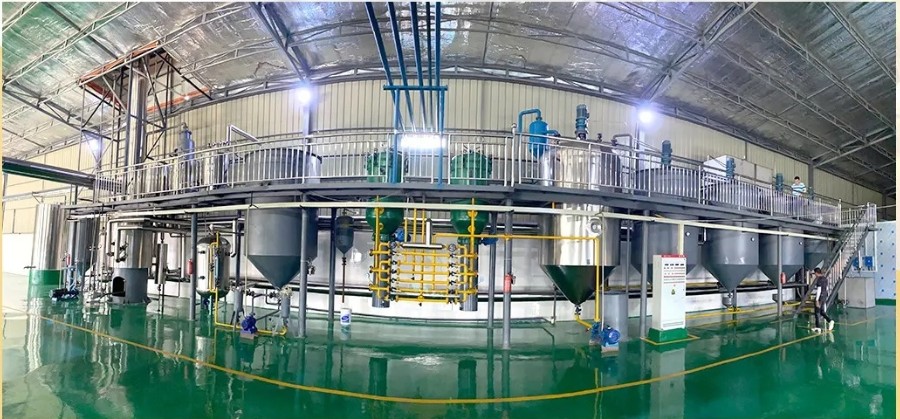

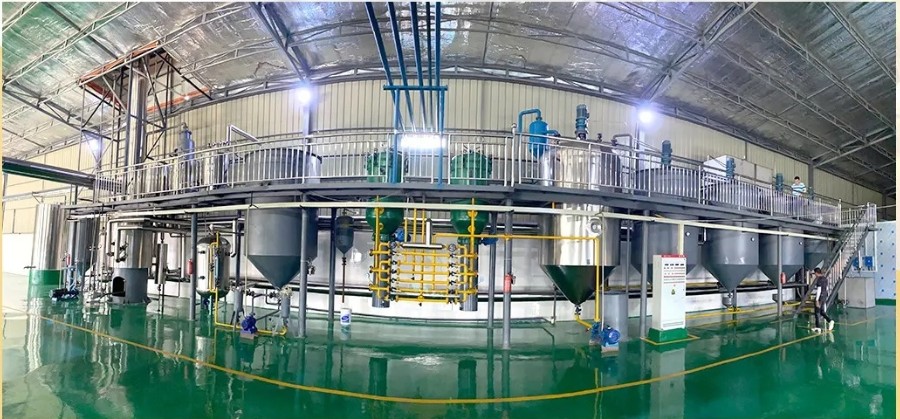

Sample Project Pictures of Cooking Oil Refining Production Line